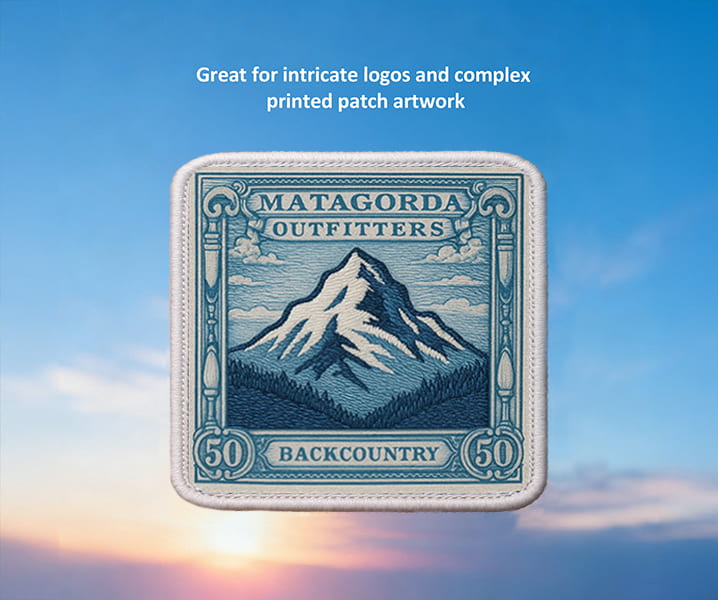

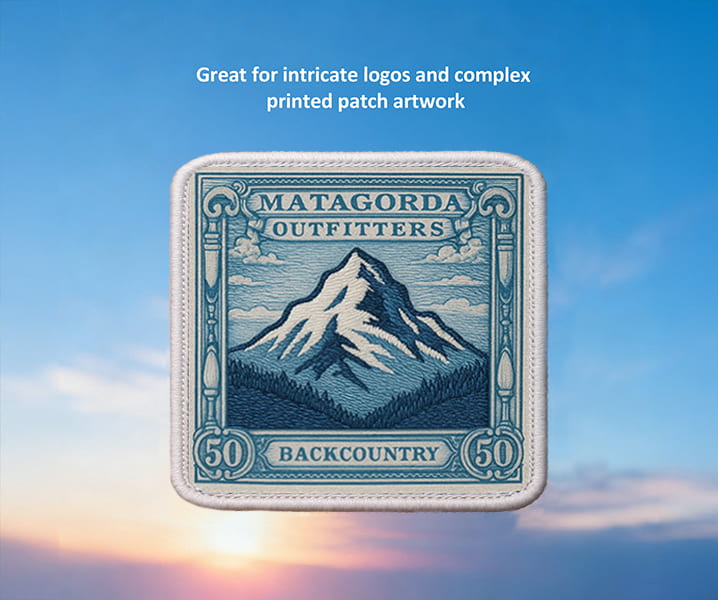

Photo-Real Detail, Light Weight, and Fast Turnarounds

You can get artwork accuracy with printed patches—smooth gradients, tiny text, full-color photos, and complex logos at small sizes. We build printed patches that look sharp, sit flat on apparel, and hold up to real-world wear at AquaPatches (an AquaDigitizing product).

What Are Printed Patches?

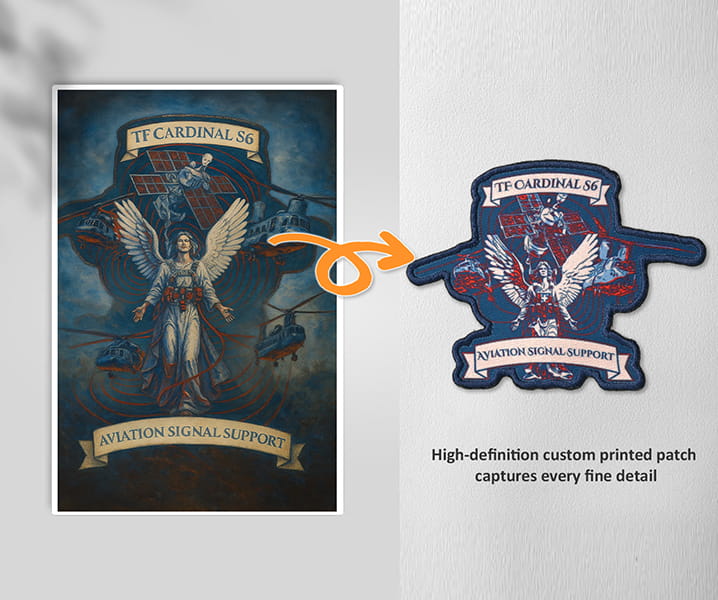

Instead of threading your design, printed patches reproduce your art directly onto a durable textile layer (or PVC film) and finish it as a patch. When you print the design, you get:

Some common manufacturing methods are sublimation on twill, DTF/transfer prints, and screen-print hybrids.

AquaPatches: Why You Should Choose Us

PVC vs. woven vs. printed

PVC

High resolution for thin lines and microtext; flatter than embroidery.

woven

It shines with bold shapes and larger sizes with embroidered patches.

printed

Printed patches: For photographs, gradients, or small type with a lot of colors.

Printed patches are the best

- Graphics, brand marks, and collabs for merch and streetwear.

- Hospitality and uniforms: Multicolored logos that match brand guidelines exactly.

- A date-specific artwork with gradients and small type.

- We do full-color crests and commemorative runs for schools and clubs.

- Labels and caps for retail: Slim profile, no heavy stitching.

Finishes, backings, and materials

Materials / Printing Methods

- It’s great for gradients and small details because of its vivid color on a woven base.

- It’s versatile, has a strong color pop, and has a soft hand.

- Hybrid screen-printing: Spot-color brilliance with abrasion-resistant topcoat.

Edges / Borders

- Heat-cut (laser-cut): Sharp, sealed edges with heat-cut shapes.

- For classic badges, there’s an optional bold, rounded border.

BACKGROUNDS

- For kits and bulk programs, iron-on (heat seal) is quick to apply to cotton, denim, and twill.

- For uniforms and frequent washing, sew-ons are the best.

- Removable or replaceable patches for carriers, bags, and modular clothes.

- Testing adhesives: Short-term events, sampling, and layout.

The AquaPatches Workflow

Send Your Artwork

Upload your PNG, JPG, AI, or EPS along with size, quantity, and backing preferences.

Review Digital Proof

Ensure threads, borders, and placement look perfect before production begins.

Production & QC

We stitch your patches on commercial machines with strict quality control.

Worldwide Shipping

Fast global delivery with friendly support for reorders anytime.

Print-Perfect Patch Design Tips

- If you can, export vectors: AI, EPS, or SVG ensure crisp type and edges; high-res PNG is fine for photos.

- Keep small text above practical minimums; we’ll flag risky lines in proofing.

- Boost contrast: Make sure foreground and background colors are clearly separated.

- You don’t want critical details sitting on the edge of laser-cut shapes, so leave safe margins.

- Preview at real size: What looks good on a 27″ monitor might look weird on a 2.75″ patch.

Care and application

(quick) Iron-On Guide:

- Pre-press garment for 3–5 seconds on a hard surface without steam.

- Place patch; cover with cotton cloth.

- For 15–25 seconds (front), then 10–15 seconds (back).

- Let cool 60–90 seconds. Re-press edges if necessary.

You’ll want a perimeter stitch if you’re going to use it heavily or for industrial laundering.

Care:

- Don’t wash for 24 hours.

- Put it in the washer inside-out on a gentle cycle, cold or warm.

- When ironing, use a pressing cloth instead of direct high heat.

- Skip harsh chemicals and high-temp tumble cycles on DTF/transfer faces.

Getting a Quote - What affects it

- Size and shape of patches

- Reduced unit cost with bulk tiers

- The backing (iron-on, sew-on, hook-and-loop, adhesive)

- Optional finishes (merrowed rims, special topcoats, retail cards)

You’ll also get budget-friendly tweaks – like optimizing size or simplifying micro-elements – without changing the look.

Are you ready to standardize your department's logo?

Are you ready to get photo-realistic patches? Your artwork and specs will be proofed, produced, and shipped by AquaPatches so they match your brand perfectly.

FAQs

We print on quality bases with protective finishes and proof for contrast. Follow care guidelines and they’ll hold color through normal wear cycles.

Yes—that’s a prime advantage. Sublimation and DTF capture photographic detail far better than thread.

Yes—choose the right base and backing. For heavy wash and abrasion, pair iron-on with a quick perimeter stitch or select sew-on.

AI, EPS, and SVG for vectors; high-res PNG or JPG for photos. We’ll handle color conversion and outline or embed fonts as needed.

We’ll match closely within textile tolerances, testing against your garment colors to avoid low-contrast traps.

Absolutely—your sizes, shapes, color profiles, and backings stay on file for fast, consistent reprints.